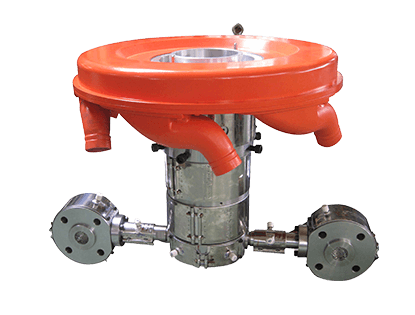

Extrusion Die Head

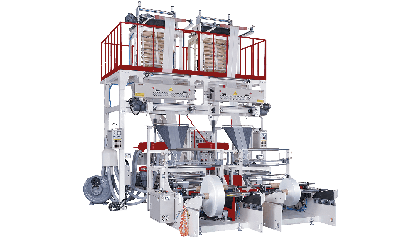

Blown Film Extrusion is one of the processes to produce plastic film products such as food packaging film, industrial film, agricultural film, medical film, etc. The main polymers materials are LDPE, HDPE, PP, PE. The Extruder Blown Film Die Head is the core component which is called the "HEART" of the Plastic Film Blowing Machine. The main function of Die Head is to distribute the melted polymer evenly so that the thickness measured around the circumference of the tube being produced is uniform. It is the key factor to ensure a quality film.

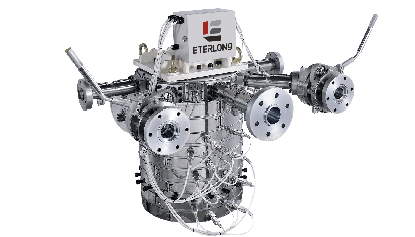

Since there are kinds of materials will be extruded at the same time, the flow channel with special design helps polymers to flow smoothly without any residue. The design of Die Head is available to divided into spiral and stackable type which both have their characteristics. As the need of marketing trend and the transformation in blown film industry, it allows kinds of additives to improve its functional advantages including water-proof, anti UV, stabilizer, recycled material and so on. Eterlong is available to offer Multi-Layers Extrusion Die Head from 3 up to 11 layers for customers to choose which is also customized.

The characteristics of these kind of Die Head is focus on its high speed of material change. It saves more time for customers to change the material and shorten the labor time.

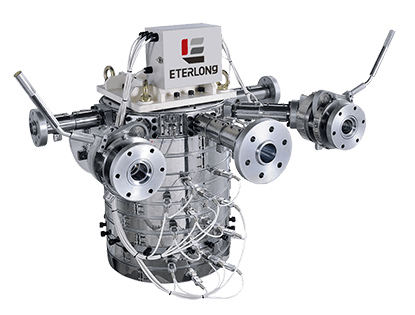

IBC Die Head is a type of Extrusion Die Head with Inner Bubble Cooling System.

If customers would like to get the promotion on productivity, IBC Extrusion Die Head will be a great choice for them. With the specific cooling system, it is available to increase the overall capacity. Besides, to equip with the different design of Air Ring will help the productivity get addition as well.

Since there are kinds of materials will be extruded at the same time, the flow channel with special design helps polymers to flow smoothly without any residue. The design of Die Head is available to divided into spiral and stackable type which both have their characteristics.

The characteristics of these kind of Die Head is focus on its high speed of material change. It saves more time for customers to change the material and shorten the labor time. The special design of the channel allows the molten film to flow pass smoothly with average speed around the circumference without any residues. Further, it is available to lower the waste of the material use as well.

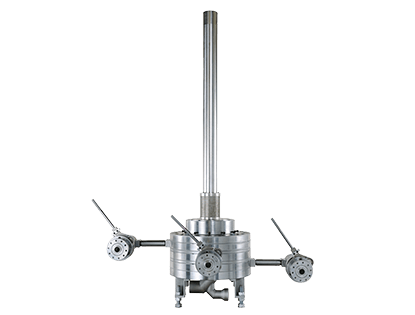

Single Layer LDPE and HDPE Extrusion Die Head is a commonly used type of blown film die which Eterlong has rich manufacturing experiences. With the rich experiences of this type of Extrusion Die Head, it is available for customers to choose the suitable collocation of components to meet their requirements.