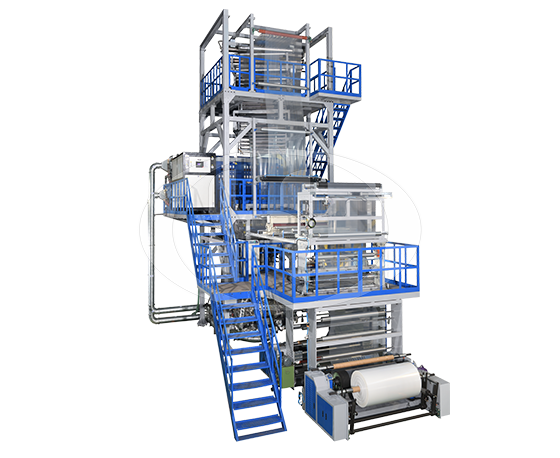

Film with Fish-eye, Arrows Lines and Coking Spots

Blown Film Extrusion Troubleshooting

| Cause (s) | Possible Solution (s) |

|---|---|

| Improper operating in material exchange |

|

| Melt temperature is too high or too low |

|

| Raw materials contain impurities |

|

| Uneven gels mix |

|