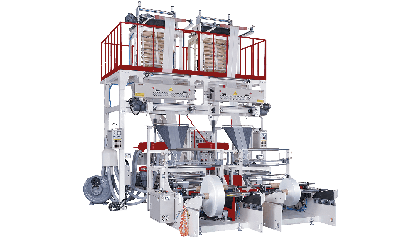

Blown Flim Take-Up Unit (Haul-Off)

The Take-Up Unit (Haul-Off) is a device set at the highest part of the Plastic Film Blowing Machine and main to pull up the blown film bubble tube which extruded out from the Die Head. The main function of Take-Up Unit is to flatten the bubble tube into lay flat film for the following process of Blown Film Winder. Further, the line speed (take-up speed) is the primary device to control the film thickness and the stability of film as well.

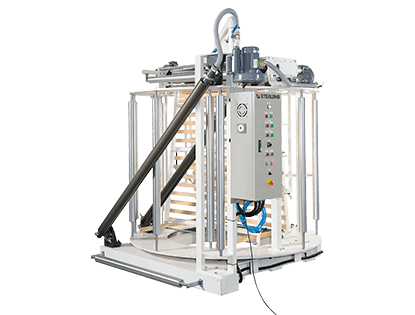

The main function of Vertical Oscillating Haul-Off System is to distribute the uneven variations uniformly in order to make the film average. Different from the horizontal one, the nip rollers stand straight with 90-degree and typically defend for the use of flat film rolls that are bigger than 3 meters. However, the characteristic is that the film will not be influenced by gravity and still keeps the good quality.

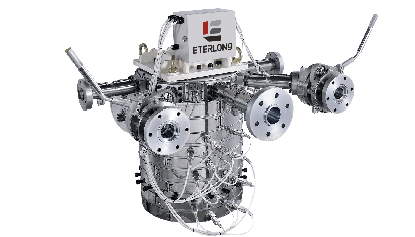

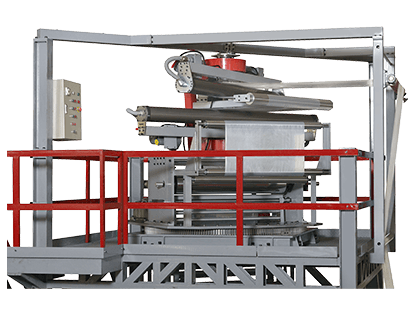

Horizontal Oscillating Haul Off apply to different Plastic Film Blowing Machines such as Single Layer, Multi-Layers, and Co-Extrusion. The main function of it is to distribute any uneven variations uniformly to let the thickness of film averagely.

Setting in the highest part of Plastic Film Blowing Machine, the most classic type of Take-Up Unit is suitable for most Blown Film Machines. Different with the Oscillating Haul-Off, the volume is smaller and not take spaces.