Quality Control and Productivity

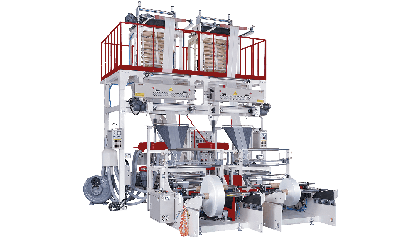

Process capability is a statistical measurement of process to produce each part of products with a specific standard. Focusing on the control of quality and quantity, process capability is a critical characteristic of ETERLONG. It composed of lots of factors including the product design, material, machine, equipment, method, skill, measurement, etc. For ETERLONG, we focus on the quality and quantity of process capability. Quality means the comprehensive quality control and implement on the whole process of production. Quantity is based on the machines and equipment which represent the productivity of a company. ETERLONG owns the professional mechanicals of CNC Lathe Machine, CNC Milling Machine, Drilling. These precision devices achieve the technique of 90% made in house.

ODM SOLUTIONS

Production Process

Once an order has been received, the order review will be our first step of process capability. In this part, we discuss with our customer continuously in order to meet their requirements and bring the best service for them. Standing in customers’ shoes, we find out the most suitable collocation of machine to reach the highest economical benefits for our customers. When the order moves to the production phases, the detective process becomes the most significant point. To make sure the steel materials without any defects. Also, we do some processing (heat treatment) on it and use Ultrasonic Sensing to check the completeness of material which called the input quality control. Process quality control which plays an important role and show the productivity of a company. By using the CAD, CAM and SolidWorks to support the technicians on computer work. Using the computers to conduct analysis, simulation, design, drawing and to plan the manufacturing projects and control the whole process of producing.

Quality Measurement

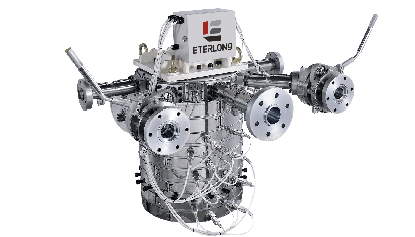

In order to guarantee the quality of Die products, we use different precision devices to check inspect each part. We use kinds of detection tools including Height Gauge, Vernier Caliper, Inside/Outside Micrometer, Roughness Tester and Equotip Hardness Tester. To reach the high performance of Die Head in Film Blowing as to produce the plastic film, all the detected processes are indispensable. For the design control, we use the Mold Flow Analysis. We utilize mold flow simulation software to conduct finite element analysis of simulation results of the effects of various necessary processes to detect and check the best symmetry and balance point of pressure distribution at the end of the mold flow. The method is applied in design of extrusion dies and analysis of co-extrusion and blown film manufacturing processes, to help enhance functionality of films, promote the integration of new & old equipment and technologies, improve client’s film quality and output, and reduce plastic waste and energy consumption. All these factors assemble a coherent cycle to follow up. Besides, we got lost of satisfy feedback from our customers about the well performance of our products. By these opinions, we find out our advantages and shorts that need to be changed. Through a succession of advancement and amelioration, these comments became one of the reasons keeps us improving.