SWOP 2019

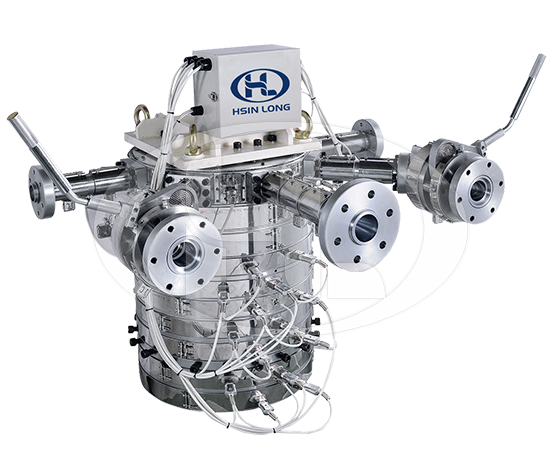

Why HSIN LONG?

HSIN LONG, the specialist in design and manufacturing experience of Blown Film Machine in TAIWAN. Our mission is “Providing the best quality and world-class components to the end users through innovative technology.”

HSIN LONG Blown Film Machine and the related components are easy operation and efficient, especially bringing out the best in Blown Film Technology to meet the requirements of each product and focusing on the feedback from customers.

HSIN LONG has gained a lot of experiences in Mono (Single) Layer to Three Layers Blown Film Machine which are based on the requirements of different Film Width, Output, and Materials of the end users. The film can be used as daily plastic film such as general garbage bag, general plastic bag, food packaging film, plastic wrap… etc.

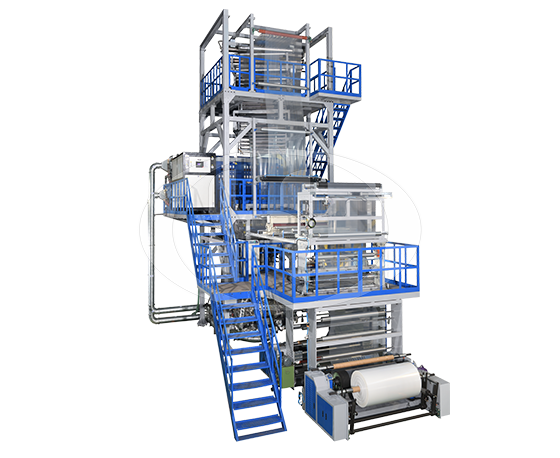

Three Layers ABA Co-Extrusion Blown Film Machine

Three Layers ABA Co-Extrusion Blown Film Machine, comprises two extruders only, it is superior and much more economic comparing to an ABC three layers machine, it can be used in T-shirt bag, garbage bag, shopping bag and general purpose film. Normally, HDPE or LDPE can be used in A-A Layer as the main raw material and Calcium Carbonate (CaCo3) or recycled material can be used in B Layer. It decreases the material consuming and improves the economic benefits of films.

The Computer-Aided Design (CAD) and Temperature Control Technology import into HSIN LONG’s Three Layers ABA Co-Extrusion Blown Film Machine. Moreover, Three Layers ABA Co-Extrusion Blown Film Machine can mix up to 70% recycled materials or Calcium Carbonate (CaCo3) in the B Layer which to decrease the production cost accordingly. On the other hand, HSIN LONG’s ABA Machine changes color masterbatch are extremely fast because the channel design in the machine’s spiral channels the flow of plastic material and therefore invites less residue buildup, thus reducing color change times and reduces waste of product.

HSIN LONG’s ABA Machine consists of two similar sizes’ extruders. The general screw diameter (extruder size) specifications combine a 45mm with a 55mm or a 55mm with a 65mm which depend on requirements of the final applications.

Features

- High Use of Recycled Materials or CaCO3 (Up to 50~ 70%) in B Layer.

- Fast Color Change.

- Material Cost Reduction.

- Enhance the Film Strength and Evenness.

Specifications

- Material: HDPE, LDPE, LLDPE, Recycled material, CaCO3, Virgin Raw Material

- Output Range: 50~250 Kgs/Hr (depends on Extruder Size)

- Screw Diameter (Extruder Size): 45mm~100mm (Customized)

- Film Width: 450mm~1600mm (Customized)

-

Film Thickness:0.008mm~0.1mm (Customized)

(※The effective output will depend on Type of Material)

Application

- Liner bags

- T-shirt bag

- Garbage bag

- Shopping bag

- General purpose film

ABA Double Die Type Blown Film Machine

HSIN LONG’s ABA Double Die Type Blown Film Machine suppliers higher output by using two Die Head in the same time. Comparing to two individual machines, the minimum space is needed and it enhances the output and efficient. The Double Die Type Blown Film Machine can produce different film widths on each Winding Unit at the same time.

Specifications

- Material: HDPE, LDPE, LLDPE, Recycled material, CaCO3, Virgin Raw Material

- Output range: 30~120 Kgs/Hr (depends on Extruder’s Size)

- Screw Diameter (Extruder Size): 55mm~75mm (Customized)

- Film Width: 450mm~1600mm (Customized)

-

Film Thickness:0.008mm~0.1mm (Customized)

(※The effective output will depend on Type of Material)

Application

- Liner bags

- T-shirt bag

- Garbage bag

- Shopping bag

- General purpose film

Visit information

ABOUT SWOP 2019

Organized by Messe Dusseldorf (Shanghai) Co., Ltd. and Adsale Exhibition Services Ltd., Shanghai World of Packaging(swop) is the essential event for the food, beverage, confectionery, baked goods, pharmaceuticals, cosmetics & daily care products, non-food consumer goods and industrial goods sectors. swop is the comprehensive platform not only meeting current demands for the entire supply chain but also identifying packaging trends for the future.